ERA Environmental Management Solutions has made some important upgrades to our EMS software that affects how users will generate their Toxic Release Inventory (TRI) reports for the2012 calendar year and future reports.

These upgrades are designed to ensure your reports are accurate and in compliance with current federal regulations.

Modified Handling of Glycol Ethers

The EPA has mandated that two specific Glycol Ethers should not be included in TRI reporting under toxic category N230:

- 110-80-5 2-Ethoxyethanol

- 109-86-4 2-Methoxyethanol

Instead, these two substances should be reported separately from N230 and should not be included in the threshold determinations for that category.

Accordingly, the ERA-EMS will no longer include your annual usage amounts for these two Glycol Ethers against the N230 reporting threshold. Instead, they are treated individually and have their own reporting thresholds based on how they have been used:

- Manufactured reporting threshold: 25,000 lbs.

- Processed reporting threshold: 25,000 lbs.

- Otherwise Used reporting threshold: 10,000 lbs.

These two Glycol Ethers are determined against these reporting thresholds separately. They are not combined for threshold determinations. If your usage exceeds this threshold, the individual Glycol Ether will be reported separately.

For those clients that use 2-Ethoxyethanol or 2-Methoxyethanol in their facility, this will change your overall reported usage submitted for category N230 compared to previous years using the ERA-EMS. The majority of users will not be affected by this change.

This change to TRI Reporting is handled entirely by the ERA-EMS and no additional action is required on your part. Simply process your TRI report as usual.

This change will not affect how other Glycol Ethers are reported or calculated against the N230 reporting threshold.

Improved TRI Treatment Codes for Metals

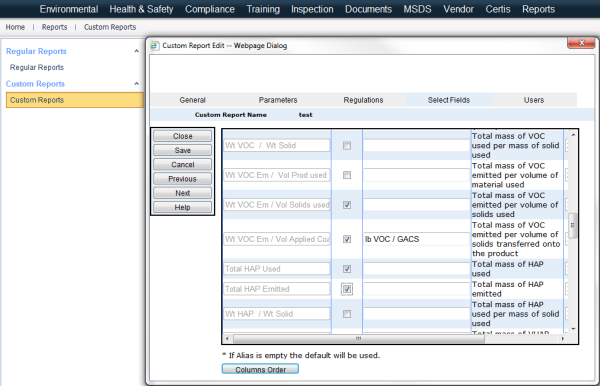

The ERA-EMS now allows users to specify specific treatment codes for metals contained in waste streams. You can set up these new waste stream codes in the waste stream set up menu.

Previously, a single treatment code could be assigned to a waste stream, regardless of its contents. However, in order to offer greater flexibility and compatibility with TRIMe Web reporting, users can enter a separate waste treatment code for the metals contained within each waste stream.

For example, as shown in the image below, you can assign the treatment code M56- Energy Recovery to your waste stream non-metals, and treatment code M24 – Metals Recovery to your metals.

Allowable Treatment codes for metals under TRI reporting are as follows:

Recycling/Transfer for Recycling

M24 – Metal Recovery

M26 – Other Reuse/ Recovery

M93 – Transfer to Waste Broker – Recycling

Transfer of Metals

|

M10 |

Storage Only |

|

M41 |

Solidification/Stabilization - Metals and Metal Category Compounds only |

|

M62 |

Wastewater Treatment (Excluding POTW) - Metals and Metal Category Compounds only |

|

M64 |

Other Landfills |

|

M65 |

RCRA Subtitle C Landfills |

|

M66 |

Subtitle C Surface Impoundment |

|

M67 |

Other Surface Impoundments |

|

M73 |

Land Treatment |

|

M79 |

Other Land Disposal |

|

M81 |

Underground Injection to Class I Wells |

|

M82 |

Underground Injection to Class II-V Wells |

|

M90 |

Other Off-Site Management |

|

M94 |

Transfer to Waste Broker - Disposal |

|

M99 |

Unknown |

Action required: to complete your TRI report properly, you will need to assign the proper waste treatment code to your waste streams. If you do not set this up before generating your TRI report you may not have correctly validated information in your report.

Montreal, QC – ERA Environmental Management Solutions (ERA) has been awarded the contract to supply Oshkosh Corporation with

Montreal, QC – ERA Environmental Management Solutions (ERA) has been awarded the contract to supply Oshkosh Corporation with