Manufacturers around the globe have noticed an uptick in the demand for aerosol products – and if you are a user of aerosol products or a manufacturer, you might find yourself surprised at how the switch in North America to the Globally Harmonized System (GHS) has affected the requirements for workplace safety compliance. Our chemical safety specialists have taken a deep-dive into these regulations and this article will give you a straight-forward and condensed guide with everything you need to know.

Manufacturers around the globe have noticed an uptick in the demand for aerosol products – and if you are a user of aerosol products or a manufacturer, you might find yourself surprised at how the switch in North America to the Globally Harmonized System (GHS) has affected the requirements for workplace safety compliance. Our chemical safety specialists have taken a deep-dive into these regulations and this article will give you a straight-forward and condensed guide with everything you need to know.

The surge in the demand for aerosol products has accelerated the expansion of companies to cater for global markets. Every country has adopted different versions of United Nations Globally Harmonized System Hazard Communication (UN GHS HAZCOM) and as a result, countries have imposed different regulations on aerosol products. This necessitates the following question: does the manufacturing company comply with the regulations imposed locally or those imposed by the importing country? It turns out that the mass export of aerosol products mandates the manufacturing companies to comply with the laws and regulations imposed in the country importing the aerosol products.

Keep reading to find out how to ensure your aerosol products are in compliance with the necessary regulations so that you don’t get hit with any fines should an OSHA auditor pay you an unexpected visit. We’ll be looking at Workplace Hazardous Materials Information System (WHMIS) 2015 and OSHA Hazard Communication Standard (HCS) 2012.

Meet the Humble Aerosol

Aerosol products are numerous and pervasive in the manufacturing workplace – so much so that we often forget how much these powerhouse products do for us… and the inherent safety hazards or emergencies that misuse can put us at risk for. Typically, aerosols are found in applications like paints, coatings, and personal care products, though your workplace can be using a vast range of other aerosolized products.

From a regulatory perspective, an aerosol is defined as a material that is dispensed in the form of a mist, spray, or foam, and they are usually dispensed by pressurized propellants in non-refillable receptacles made of metal, glass, or plastics containing compressed, dissolved, or liquefied gases under pressure.

- Health and Safety professionals need to be familiar with the different types of aerosols that can pose a risk to human health and workplace safe operations: flammable, foam, and spray aerosols.

- Flammable aerosols are characterized by a product that consists of flammable agents which are prone to ignition as the material is being dispensed from the aerosol dispenser. This excludes any product that contains less than 0.1% flammable components or that has a heat of combustion less than 20kJ/g.

- Foam aerosols are characterized by a dispenser which dispenses the material in the form of a gel, paste or mousse and has a spray distance that does not exceed 15 cm.

- Spray aerosols refers to all other aerosols that do not dispense materials in the form of a gel, paste, or mousse.

Spot the Difference: Regulations Across North America

Surprisingly, the regulatory transition to the Globally Harmonized System (GHS) has not been straightforward for aerosol products. Health & Safety professionals need to take the time to make themselves aware of the notable changes and pitfalls related to aerosol labeling and hazard communication.

Surprisingly, the regulatory transition to the Globally Harmonized System (GHS) has not been straightforward for aerosol products. Health & Safety professionals need to take the time to make themselves aware of the notable changes and pitfalls related to aerosol labeling and hazard communication.

OSHA aligned its HCS in 2012 with the 3rd version of UN-GHS, while in Canada WHMIS 2015 aligned its standards with the 5th version of UN-GHS… however the environmental hazards group and the “Aerosols” hazard class within the physical hazards were not adopted. For Aerosols, WHMIS 2015 continues to align with the evaluation criteria proposed in the 3rd revision of the UN-GHS. Thus, the same criteria are considered when evaluating the flammable aerosols classification under WHMIS 2015 and OSHA HCS 2012 (refer to "Workplace Hazardous Material Information System (WHMIS) Training Manual," 2016) for more information.

Interpreting the Rules: What Do I Need to Know

Now that you have the regulatory background, it’s time to get to work! Our team of chemical safety specialists have provided a simple breakdown of what you need to know for the properlabeling and hazard communication for aerosol products.

- If a product in an aerosol dispenser contains one or more flammable components which are classified as flammable gases, liquids, or solids, according to the GHS criteria, the product must be classified as one of the two categories for this hazard class, as per the 3rd revision of the UN-GHS.

- Substances or mixtures that are pyrophoric, self-heating or water-reactive, are never used in aerosols and thus are not covered under flammable components.

- As per the 3rd revision of the UN-GHS, a flammable aerosol can be classified in one of two categories of the hazard class. The classification is evaluated based on the aerosol’s chemical heat of combustion and, if applicable, based on results of an ignition distance test, foam test (foam aerosols), and enclosed spray test (spray aerosols).

Here are some of the regulation highlights that you need to know:

The aerosol is classified based on its components as either an extremely flammable aerosol (Category 1) or a flammable aerosol (Category 2). Any aerosol that has not been evaluated according to flammability classification procedures should be classified as an extremely flammable aerosol (Category 1). In addition, aerosols should not be classified as flammable gases, liquids, or solids. However, they may also be classified as gases under pressure, and depending on their state when packaged fall in one of four groups; compressed gas, liquified gas, refrigerated liquified gas, or dissolved gas (per United Nations, "Globally Harmonized System of Classification and Labelling of Chemicals (GHS), Third revised edition,” 2009).

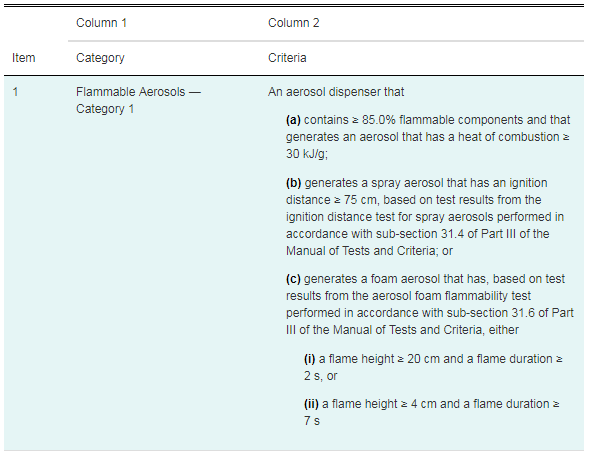

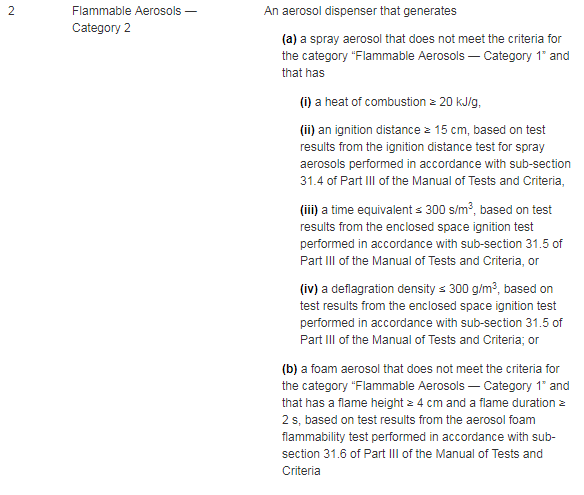

A detailed outline of the classification criteria for flammable aerosols is shown in Canadian Hazardous Products Regulations.

Table 1. Classification Criteria for Flammable Aerosols

The 4th revision of the UN-GHS made modifications to the “Flammable Aerosols” hazard class.

- The name of the hazard class was modified to “Aerosols” and an additional hazard category was added, to account for non-flammable aerosols.

- Any aerosol which does not meet the evaluation criteria to be classified as an extremely flammable or flammable aerosol should be classified as a non-flammable aerosol (Category 3).

- In addition, aerosols can no longer be classified as gases under pressure.

After a comprehensive review of the regulations imposed on classifying aerosols, it is concluded that the same evaluation criteria are applied by WHMIS 2015 and OSHA HCS 2012 despite that WHMIS has aligned with the 5th version of the UN-GHS and OSHA HCS 2012 has aligned with the 3rd version of the UN-GHS.

How Do These Regulations Affect my Business?

First and foremost, your responsibility is to ensure that all aerosols manufactured or used on site are properly classified according to your nation’s regulation. As stated above, the same evaluation criteria is used for aerosols by the most recent WHMIS and OSHA iterations.

You will need a complete, GHS-compliant Safety Data Sheet for any aerosol products on hand and accessible to anyone who is at an exposure risk. This SDS should be available to your staff both in printed form and digitally.

You’ll need comprehensive data on the components of your aerosol products and chemical expertise in order to follow the classification guidelines of the UN Purple Book, and the ability to do any required threshold determinations. Typically, manufacturers will have staff with chemical expertise crunching this data. If you’re getting aerosol products supplied to for your manufacturing process, you should request a complete 16-section SDS from your supplier(s).

For any manufacturer with more complex processes, or more than a small handful of SDSs to manage for aerosols or otherwise), it is recommended to implement a formal SDS Management system – one that digitally sorts, shares, and saves your SDSs. This type of system can be configured to let employees in roles that are at exposure risk to view relevant SDSs on demand.

Whether or not you chose to implement an SDS Management Software or not, you will need to keep your SDSs up to date and accessible. Should a health & safety inspector pay your site a visit, they will undoubtedly check to see if you are complying with this fundamental part of both WHMIS and OSHA regulations.

No matter if your SDS Management or SDS Authoring needs are complex or simple, the first step to complete GHS compliance is understanding the fundamentals of SDS Authoring and Management. That’s why we recommend you download this free eBook “The GHS SDS Authoring Handbook” which is full of useful information about complying with the UN’s Globally Harmonized System.

This Blog was Co-Authored By:

November 3, 2017

Comments