The Ground Level Concentration Max (GLCMax) calculation is among the most important emission calculations that Texas manufacturers using tanks in their operations should know inside and out. Not only is it important for regulatory compliance with Effects Screening Levels (ESL), but it is also a powerful tool for assessing materials to find more efficient and cost-effective alternatives. GLCMax allows you to measure your environmental impact in order to reduce your footprint and find better materials.

The Ground Level Concentration Max (GLCMax) calculation is among the most important emission calculations that Texas manufacturers using tanks in their operations should know inside and out. Not only is it important for regulatory compliance with Effects Screening Levels (ESL), but it is also a powerful tool for assessing materials to find more efficient and cost-effective alternatives. GLCMax allows you to measure your environmental impact in order to reduce your footprint and find better materials.

Unfortunately, GLCMax is also one of the least understood and documented emissions calculations for tank owners and operators. Although GLCMax calculations are required by Texas state regulators, the TCEQ (Texas Commission on Environmental Quality) is still in the process of developing their final GLCMax documentation. This scenario makes using GLCMax correctly a difficult task.

That is why ERA’s environmental scientist team has developed these helpful tips when it comes to understanding how to make the best use of the GLCMax Calculation.

Chemical Flexibility: Where GLCmax Gets Complicated

Most businesses are not permitted to change the materials going through their tanks on the fly, even if they perform GLCMax calculations. This ability only applies to businesses with a chemical flexibility provision written into its permit. Common examples of these facilities are those like refineries where changes in products can be a business requirement.

If your facility does have a chemical flexibility provision, you will need to use GLCMax calculations before you introduce a new material (more detail on that in Tip #1). If you do not have a chemical flexibility provision, you’ll still use GLCMax calculations to demonstrate that the materials you do use on site don’t exceed the effects screening level (ESL).

Understanding the GLCMax Calculation

GLCMax represents a hypothetical, though unlikely, worst-case scenario that produces the maximum quantity of hazardous air pollutant emissions resulting from filling all your applicable tanks simultaneously. In this case, all applicable tanks refers to any tank that will contain the hazardous chemical. For the majority of businesses, this means all tanks on site.

Typically, most tank owners/operators load and unload each of their tanks individually as need be, rather than filling all of their tanks at once. Although this makes reaching your calculated GLCMax emissions in the real world highly unlikely, the TCEQ is charged with regulating your potential to emit (pte) and bases your permits and activities on worst case scenarios.

Whenever you load or unload a substance into a tank, the transferred materials release a certain amount of hazardous air pollutants (HAPs) – known as working losses. The rate HAPs are emitted are laid out in the AP-42 documents used by the Oil & Gas and Chemical industries.

GLCMax calculations sum all of these working losses under the assumption that all your tanks are being loaded to maximum capacity at once to come up with a final number the TCEQ can use to judge your maximum potential emissions.

The TCEQ applies a site-specific air modelling calculation to determine a Unit Impact Multiplier for every tank on site. These are then written into your permit by your regulators before you begin operations and are part of the process of permitting for chemical flexibility. This Unit Impact Multiplier varies according to several variables about your site, the unit (e.g. a storage tank) and its surroundings. For example, an isolated small tank will have a lower Unit Impact Multiplier than a large tank next to a public space.

Your resulting maximum potential emissions of a particular chemical are then compared to the chemical’s Effects Screening Level (ESL), which has been determined by the TCEQ under the Clean Air Act (CAA). If your emissions of the chemical in question land below the standardized ESL, your emissions are within permissible limits. It’s important to note that ESLs can change periodically, and so you should have someone from your EH&S team dedicate research time to tracking your applicable ESLs. If you use an EHS management software program, check to see if it automatically tracks and updates ESLs for your chemicals - it should.

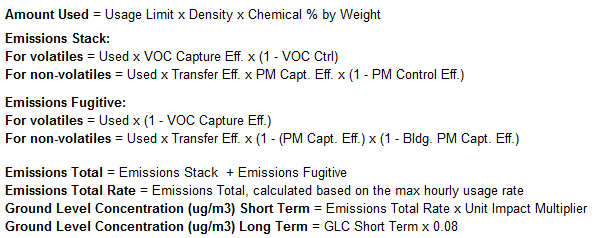

Here’s one of the ways that ERA calculates long term and short term Ground Level Concentrations for some types of sources. You should use the AP-42 calculations specific to your style of tanks. In essence, GLCMax is the summation of all your GLC values for all your potential sources:

Tip #1: Calculate GLCMax as Needed, not on a fixed schedule

Unlike most emissions calculations, GLCMax values don’t need to be completed or submitted by a certain annual deadline.

Instead, GLCMax should be calculated any time you want to introduce a new material into your tank systems – which is as often or as little as your operations require. If you often switch out materials for better ones you’ll have more GLCMax calculation records than a business that rarely re-evaluates its materials. Remember, this only applies if you have a chemical flexibility provision written into your permit that allows you to change materials on the fly.

There’s no deadline for submitting GLCMax results to your regulators. You are obligated to have your records ready for your regulators during environmental audits. When you do get audited, you’ll need to be able to prove you did a GLCMax assessment on new products and demonstrate you didn’t go over the relevant Effects Screening Level (ESL).

So don’t wait to do your GLCMax calculations on a fixed schedule, since an unexpected regulatory audit could land in a period you aren’t prepared for. By doing GLCMax the moment it is needed, instead of trying to play catch up and fill in the blanks, you protect yourself and your reputation.

Tip #2: Make GLCMax Calculations Empower Your Continuous Improvement

GLCMax was designed to empower businesses to make decisions for themselves and to be more agile on the market. If GLCMax seem like a burden to your EH&S team, remember that without it you would have to rely on government regulators to assess all potential new materials for you and give you the go ahead once they find the resulting emissions acceptable.

GLCMax gives your EH&S team the authority to approve new materials for your business, putting decision-making power back into your hands instead of your regulators. Regulators set the ESL worst-case scenario, and as long as you’re under that emission ceiling you are in command.

That’s what makes the GLCMax calculation a useful tool for continuous improvement planning: it is one of the best ways (and a government approved method) for evaluating materials that you’re considering using. If the new material doesn’t put you over your ESL then it won’t cause a compliance issue during an audit. You are empowered to make the material change without regulatory intervention.

GLCMax is a powerhouse calculation for comparing potential materials. You should regularly compare the current GLCMax emissions of your existing materials against other available materials on the market to see which has a lower GLCMax emission result.

GLCMax is also a powerful benchmarking tool. Track your GLCMax emissions on a regular schedule (this is made much easier by automating the process) and you’ll have a handy snapshot of whether you actually are continuously improving your operations or if you’re at a standstill when it comes to tank operations. Even if you haven’t changed materials much, GLCMax can reflect how well your tanks and their control devices are doing at preventing material loss through air emissions.

Tip #3: Simplify by using the AP-42 Standard Variables

The GLCMax calculation can be challenging due to the many steps and the amount of labor and time it can take (when doing it by hand, especially for large numbers of different potential materials), however this challenge can be somewhat mitigated by the straightforwardness of the variables.

Because the TCEQ wants a worst-case scenario, they’ve standardized a fixed temperature to use for GLCMax and a variable for turnovers (constant Kn = working loss turnover factor), so the primary variable to account for is the potential material’s emissions rates and chemical components. For example, you must assume a temperature variable of 95 degrees Fahrenheit in the GLCMax formula rather than finding out the real-world meteorological data for your location - in order to calculate reasonable “worst-case” emissions.This saves you the extra steps of determining variables like temperature and turnovers.

Before you start doing any GLCMax calculations, reference the AP-42 document to determine which standardized data you should be using - in the long run this will save some significant time as you plug your variables into the equation.

Tip #4: Include All Necessary Air Contaminants and Sources

Different states have different regulations regarding which emission sources must be included in your GLCMax calculation. Before finalizing your GLCMax results make sure everything is accounted for.

For example, in Texas, manufacturers looking to add a new material to their production processes must calculate the emission rate of each air contaminant in the new material and the emission rate of any same air contaminants from already authorized materials that may be emitted at the same time from each emission point.

In other words, if you want to use a new material that includes Xylene you not only need to calculate Xylene HAP emissions from the new material but also factor in the Xylene emissions from all materials already in use that contain Xylene. This will sum up all potential Xylene emissions your facility could potentially emit if you use the new material, even though some of those emissions are currently authorized.

The very best method for ensuring you’re including all the necessary sources and air contaminants is to contact your state regulator. Although most states follow the standard GLCMax requirements, your State -- like Texas -- might have additional requirements. Since many states are still finalizing their documentation for GLCMax, we recommend emailing or phoning your regulator rather and asking them directly what the requirements are. They may even have some documentation ready to send to you.

Tip #5: Automate GLCMax Calculations and Reports for Maximum Benefits

Even with the tips and pointers from this article in mind, the GLCMax calculation can be time consuming and a source of stress. GLCMax can create a large workload for your EH&S department, particularly if your continuous improvement efforts involve evaluating several potential materials or regular internal benchmarking.

Don’t let the complexities of GLCMax calculations prevent you from finding more efficient and money-saving materials. Avoiding GLCMax could be costing you money.

The hands-down best method for maximizing the benefits of GLCMax compliance without spending hours in front of a confusing spreadsheet or the dense AP-42 document is to implement an automated system that has all the calculations and regulatory variables built in. A system like this will even be able to tap into your materials database and save you the step of entering in all the chemical data for the materials you want to compare.

When done right and used smartly, GLCMax calculations help your business make smarter decisions: find better materials that are cost-effective, reduce your environmental impact, improve your regulatory compliance record, and create a better end product. Finding an automated system that gives you all these benefits without the unnecessary time and labor? That’s the smartest decision of all.

Ask an ERA Expert:

Do you have any questions or concerns about the topic covered in this article? Want more insight? Now is your chance to ask one of ERA’s Environmental Specialists. Please leave your question or comment below and we’ll make sure one of our expert scientists responds.

This Blog was Co-Authored By:

Tags:

Air Management

September 22, 2014

Comments